Ensuring Quality Control in Manufacturing: Best Practices

Quality control is a critical aspect of the manufacturing process. It is the practice of monitoring and inspecting products to ensure they meet the desired quality standards. Without effective quality control measures in place, manufacturers run the risk of producing faulty products that could harm customers, damage their reputation, and incur significant financial losses. In this blog post, we will discuss some best practices for ensuring quality control in manufacturing.

1. Implement a Comprehensive Quality Management System (QMS)

A Quality Management System (QMS) is an essential tool for maintaining quality control in manufacturing. It provides a framework to guide manufacturers in managing and continuously improving their quality processes. A QMS should include policies, procedures, and documentation that cover all aspects of the manufacturing process, from raw material acquisition to packaging and shipping. By implementing a QMS, manufacturers can streamline their quality control efforts and ensure consistency across all stages of production.

2. Conduct Regular Inspections and Tests

Regular inspections and tests are crucial in identifying any defects or issues in production. Establishing a rigorous testing process, which may include statistical process control, can help manufacturers detect problems early on. Inspections should occur at different points in the manufacturing process, including incoming raw materials, during production, and before shipment. By conducting regular inspections and tests, manufacturers can identify problematic areas and take corrective actions to prevent the production of faulty products.

3. Provide Adequate Employee Training

Employee training plays a vital role in ensuring quality control. It is crucial that all employees involved in the manufacturing process are properly trained in quality control procedures, including how to identify and address potential quality issues. Training should cover topics such as quality standards, inspection techniques, and proper handling of materials and equipment. By providing adequate training, manufacturers can empower their employees to uphold quality standards and take proactive measures to prevent defects.

4. Foster a Culture of Accountability

To ensure quality control, it is essential to foster a culture of accountability within the organization. All employees should understand the importance of maintaining quality standards and should be encouraged to take ownership of their work. Regular performance evaluations can help identify areas for improvement and encourage employees to focus on quality. Additionally, implementing a system for reporting and addressing quality concerns can further promote accountability across the organization.

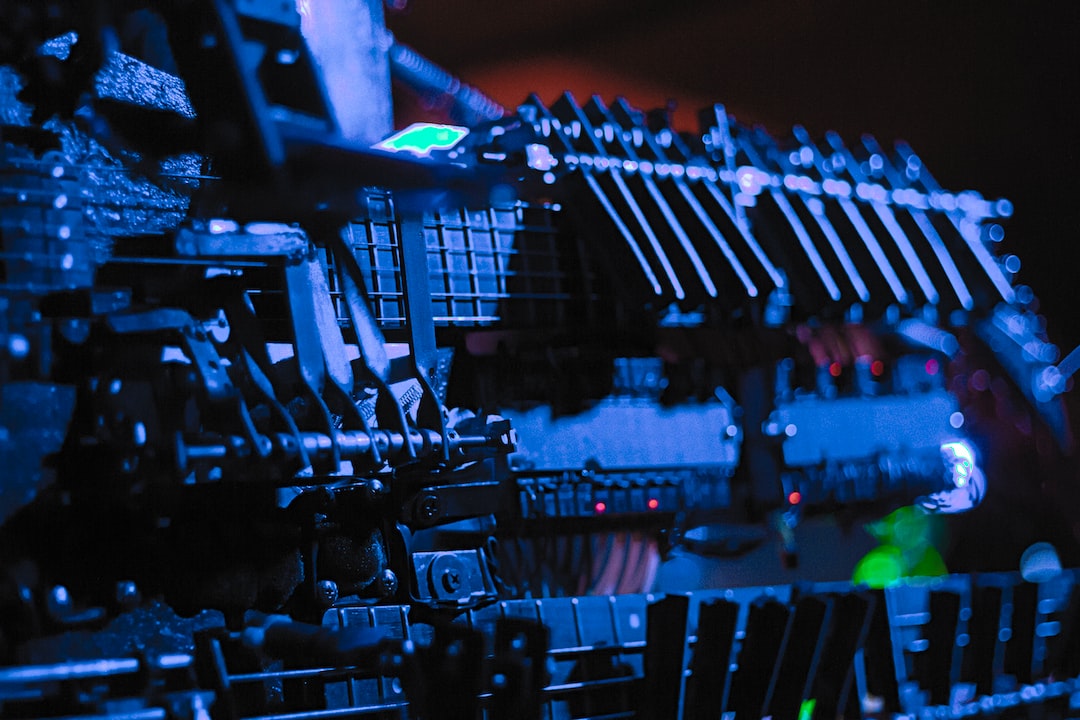

5. Utilize Technology for Quality Control

Leveraging technology can significantly enhance quality control measures in manufacturing. By implementing automated inspection and testing systems, manufacturers can reduce human error and increase accuracy. For example, machine vision systems can be used to inspect product dimensions, detect defects, and ensure consistency in appearance. Furthermore, cloud-based QMS software can improve communication and collaboration among different departments, providing real-time data and analytics for better decision-making.

6. Continuous Improvement through Data Analysis

Data analysis is an essential component of quality control. By analyzing production data, including inspection results, defects, and customer feedback, manufacturers can identify patterns and trends that may point to underlying quality issues. This data-driven approach allows manufacturers to make informed decisions and implement corrective measures to continuously improve their processes and prevent future defects.

7. Collaboration with Suppliers and Customers

Manufacturers should foster strong relationships with their suppliers and customers to ensure quality control. When working with suppliers, it is essential to establish clear quality requirements and expectations. Regular audits of supplier facilities can help assess their ability to meet these requirements. On the other hand, regularly seeking feedback from customers can provide valuable insights into product performance and identify areas for improvement.

Conclusion

Quality control is crucial for manufacturers to ensure that their products meet the desired standards. By implementing a comprehensive Quality Management System, conducting regular inspections and tests, providing employee training, fostering a culture of accountability, utilizing technology, and analyzing data, manufacturers can strengthen their quality control processes. Collaboration with suppliers and customers further enhances these efforts, ensuring that quality control is maintained throughout the entire manufacturing supply chain. By prioritizing quality control, manufacturers can deliver products that meet or exceed customer expectations, safeguard their reputation, and achieve long-term success.